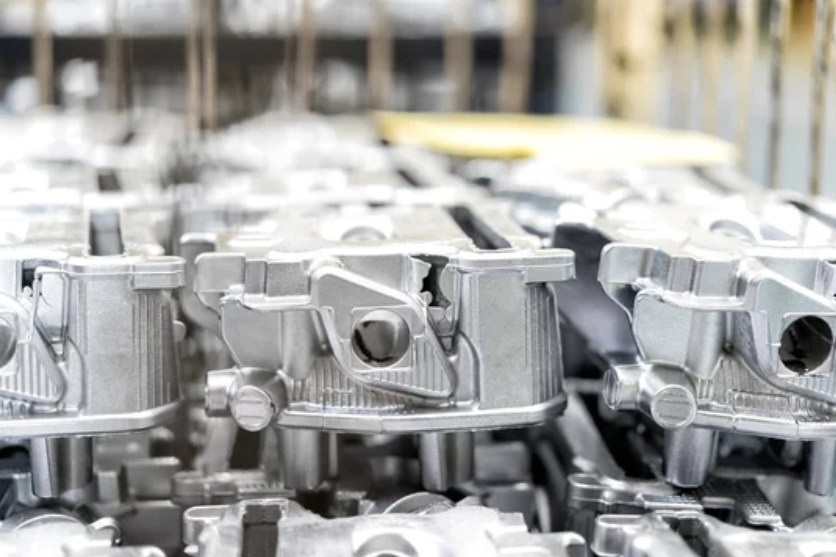

Aluminum Foundry expertise that guarantees superior product quality

Wiki Article

The Future of Light Weight Aluminum Foundries: Developments and fads Shaping the Sector

The aluminum shop industry is going through considerable transformation. Key fads highlight the importance of sustainability and effectiveness. Technologies in smart manufacturing and automation are ending up being widespread. Foundries are progressively focused on using recycled materials. This shift increases inquiries about future practices and innovations. Just how will these changes impact manufacturing approaches and market characteristics? The solutions might redefine the industry landscape in unexpected methods.Improvements in Smart Production Technologies

As the light weight aluminum shop sector evolves, developments in wise production modern technologies are ending up being significantly important for improving performance and efficiency. The integration of automation, man-made knowledge, and the Net of Things (IoT) is transforming typical shop operations. These technologies enable real-time tracking of procedures, permitting instant modifications that maximize outcome and minimize waste.Device knowing algorithms evaluate production information to determine patterns and forecast maintenance needs, lessening downtime. Robotics are significantly employed for repeated jobs, freeing skilled employees to concentrate on even more complex obstacles. Furthermore, digital twins-- online versions of physical processes-- assist in simulations that can improve layout and operational techniques.

The fostering of these wise manufacturing technologies is driving competitive advantages in the aluminum shop field. By enhancing workflows and enhancing decision-making abilities, shops can satisfy expanding market needs while keeping top notch criteria. The future of aluminum shops is undeniably linked to these technical developments.

Accepting Eco-Friendly Products and Processes

The aluminum foundry market is increasingly concentrating on environmentally friendly materials and procedures to boost sustainability. This shift includes the adoption of lasting product sourcing, energy-efficient manufacturing techniques, and effective recycling and waste monitoring techniques. By incorporating these practices, factories aim to reduce their environmental effect while maintaining competitiveness on the market.Sustainable Product Sourcing

How can light weight aluminum factories improve their sustainability efforts? Lasting product sourcing has arised as a necessary technique in achieving this goal. By focusing on recycled aluminum, shops can greatly lower their environmental impact, as recycled materials need less energy and less resources contrasted to key light weight aluminum production. In addition, sourcing products from licensed distributors that abide by eco-friendly techniques promotes responsible mining and decreases ecological influence. Foundries are additionally exploring alternate products, such as biopolymers and environmentally friendly finishes, to enhance typical light weight aluminum procedures. Collaborating with stakeholders, consisting of distributors and environmental companies, cultivates development in sourcing methods. Inevitably, embracing sustainable material sourcing not only lines up with global sustainability objectives but additionally positions aluminum foundries as leaders in environmentally accountable production.Energy-Efficient Manufacturing Strategies

Light weight aluminum shops are significantly adopting energy-efficient production strategies to enhance their sustainable material sourcing campaigns. These methods concentrate on lessening power consumption throughout the production process. Advanced technologies, such as induction melting and maximized spreading processes, are being executed to reduce the total carbon impact. Furthermore, automation and clever manufacturing systems improve functional efficiency, enabling much better power management. Foundries are additionally checking out the assimilation of renewable resource sources, such as solar and wind, to power their procedures. By focusing on energy performance, light weight aluminum foundries not only reduced manufacturing costs however also straighten themselves with global sustainability objectives, guaranteeing an extra ecologically accountable strategy to aluminum manufacturing while satisfying the increasing demand for environment-friendly practices in the market.Reusing and Waste Management

Accepting environmentally friendly materials and processes, light weight aluminum foundries are focusing on recycling and waste administration methods to improve sustainability in their operations. By integrating closed-loop systems, these facilities are lessening waste and making best use of resource performance. Scrap light weight aluminum, a conveniently offered material, is being reused on-site, substantially decreasing the need for virgin materials and decreasing energy consumption. Advancements in sorting and processing innovations additionally help with the recycling of aluminum, guaranteeing that also polluted products can be repurposed effectively. Furthermore, shops are embracing sustainable techniques such as lowering contaminated materials and promoting using biodegradable products for packaging. This commitment to recycling not just reduces environmental effect yet additionally enhances the financial practicality of aluminum foundries in an open market.The Role of Automation and Robotics

Automation and robotics are progressively changing the aluminum foundry market, substantially enhancing production effectiveness. By incorporating advanced innovations, factories can decrease labor prices while concurrently improving security requirements for their workforce. This shift not just streamlines procedures yet also places the sector for sustainable development in a competitive market.Improved Manufacturing Efficiency

Reinventing production procedures, the combination of advanced robotics and automation technologies has actually ended up being a cornerstone for aluminum factories seeking boosted efficiency. These innovations streamline operations, reduce cycle times, and enhance item quality by minimizing human error. Automated systems can monitor assembly line in real-time, enabling prompt modifications that optimize outcome. Furthermore, robotics help with the handling of harmful products, guaranteeing more secure functioning atmospheres while raising throughput. Predictive upkeep technologies additionally add to effectiveness by anticipating equipment failings, therefore minimizing downtime. As an outcome, aluminum shops can achieve better consistency in their products while responding a lot more promptly to market demands. This embrace of automation is setting a new standard for performance and functional excellence within the sector.

Decreasing Labor Expenses

The change in the direction of advanced robotics and automation in aluminum shops not only boosts manufacturing performance yet additionally plays a substantial function in lowering labor prices. By incorporating automated systems, shops can decrease the dependence on hands-on labor, which typically involves high salaries and training costs. Robotics simplify repetitive jobs such as pouring, molding, and ending up, enabling a greater output with fewer employees. This technical adjustment not just minimizes labor-related expenses but additionally enhances uniformity and top quality in production. Additionally, automation can operate around the clock, making best use of functional hours without the connected costs of overtime or shift differentials. As an outcome, light weight aluminum factories can achieve considerable financial savings while preserving affordable pricing in a progressing market landscape.Improving Security Standards

While traditional aluminum foundry procedures frequently reveal workers to harmful environments, the integration of robotics and automation greatly enhances safety standards within the market. Automated systems can execute risky tasks, such as molten metal handling and hefty lifting, minimizing human exposure to dangerous conditions. Furthermore, robotics can run in hazardous ambiences and extreme temperatures, properly lessening the risk of injury. Advanced checking innovations and expert system assurance real-time safety assessments, allowing for prompt feedbacks to prospective dangers. In addition, automation improves operations, lowering the likelihood of mishaps triggered by human mistake. As an outcome, the fostering of these technologies not only enhances security however likewise promotes a much more effective and effective workplace in light weight aluminum shops.Enhancing Power Performance in Manufacturing

As light weight aluminum shops seek to maintain competition in a developing market, improving energy performance in manufacturing has actually become an essential emphasis. By adopting advanced innovations such as high-efficiency melting heaters and automated temperature level controls, shops can notably decrease power consumption. Implementing real-time monitoring systems enables exact monitoring of energy usage throughout the production process, allowing quick changes to maximize efficiency.Furthermore, shifting to alternate energy sources, consisting of renewable options, can further reduce the carbon footprint. The integration of energy healing systems, which reclaim waste warm for reuse, is becoming progressively typical. Educating employees in power administration techniques assures that everybody entailed in the manufacturing procedure bears in mind power usage.

These initiatives not only lower functional expenses yet additionally align with international sustainability goals, placing light weight aluminum shops as accountable gamers in the sector while boosting their total competitiveness. - Precision aluminum casting

Innovations in Recycling Aluminum

Advancements in recycling light weight aluminum have actually gained energy alongside initiatives to boost energy efficiency in production. The light weight aluminum industry has welcomed innovative innovations that enhance the recycling process, lowering power intake and environmental effect. Techniques such as hydrometallurgy and brand-new sorting innovations improve the removal of light weight aluminum from scrap, boosting return rates and making certain better recycled material.

The advancement of closed-loop recycling systems enables foundries to recycle aluminum without substantial degradation in quality, making the procedure a lot more sustainable. Technologies in logistics and collection, including enhanced radar and automated sorting, have also played an important role in enhancing the efficiency of light weight aluminum healing. These innovations not just add to a round economic situation yet additionally assist alleviate the carbon footprint related to aluminum production. As the demand for lasting techniques expands, these advancements place the aluminum factory industry as a leader in responsible resource management.

Reacting To Market Demands and Customer Trends

Flexibility has actually ended up being a foundation for aluminum foundries reacting to evolving market demands and consumer patterns. As markets progressively focus on sustainability, light weight aluminum foundries are changing in the direction of environmentally friendly methods, consisting of boosted reusing procedures and minimized carbon footprints. This change straightens with consumer preferences for environmentally responsible products, driving foundries to innovate their offerings.In addition, the surge of light-weight materials in auto and aerospace markets demands advancements in aluminum alloys and casting techniques. Foundries are purchasing research and development to generate high-strength, lightweight components that satisfy rigid efficiency standards.

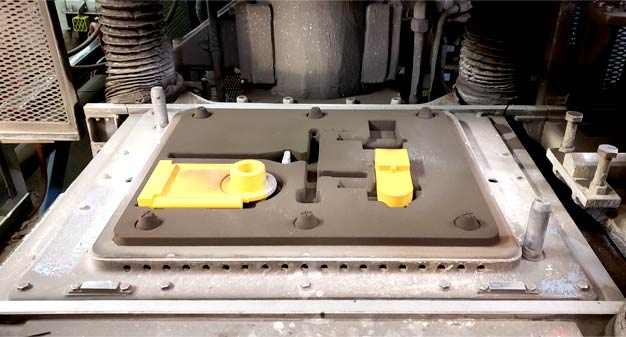

Customization has acquired traction, with customers looking for tailored services. Aluminum factories are leveraging advanced manufacturing technologies, such as 3D printing, to accommodate details client demands successfully. This responsiveness not just pleases customer demands however likewise placements light weight aluminum foundries competitively in a dynamic market landscape, ensuring their significance in an ever-changing industrial environment.

Regularly Asked Questions

Just How Do Light Weight Aluminum Foundries Influence Local Economies?

Light weight aluminum foundries considerably affect neighborhood economies by developing work, promoting need for local distributors, and adding to area development. Their operations commonly lead to boosted tax profits, which can fund essential civil services and infrastructure improvements.What Are the Security Laws for Aluminum Factory Employees?

Safety policies for aluminum shop workers consist of obligatory individual safety devices, proper ventilation systems, normal training on harmful materials, and adherence to guidelines established by work-related health and wellness administrations to decrease threats and assurance worker safety and security. - aluminum castingHow Does Light Weight Aluminum Recycling Affect Global Supply Chains?

Light weight aluminum recycling significantly reduces need for raw products, improves resource efficiency, and maintains rates. This change effects worldwide supply chains by cultivating a round economic situation, advertising sustainability, and guaranteeing a much more durable market in changing markets.What Career Opportunities Exist in the Aluminum Factory Market?

Numerous profession chances exist in the aluminum foundry industry, consisting of roles in engineering, high quality control, production monitoring, and r & d. Skilled labor positions such as mold makers and equipment drivers are also sought after.How Do International Profession Policies Influence Light Weight Aluminum Foundries?

International profession plans significantly impact light weight aluminum factories by affecting import tariffs, supply chain dynamics, and market accessibility. These factors can influence functional expenses, competition, and overall earnings within the international aluminum manufacturing landscape.By prioritizing recycled light weight aluminum, shops can significantly minimize their ecological impact, as recycled materials require less energy and less sources contrasted to primary aluminum production. Light weight aluminum factories are significantly adopting energy-efficient production methods to enhance their get more info lasting material sourcing initiatives. Automation and robotics are increasingly changing the light weight aluminum shop industry, considerably enhancing production effectiveness. The change in the direction of progressed robotics and automation in light weight aluminum shops not only enhances production efficiency but also plays a significant role in minimizing labor prices. As light weight aluminum factories seek to preserve competition in an advancing market, boosting power efficiency in production has emerged as an important emphasis.

Report this wiki page